Hi there, my name is Ahmad Khan and I’ve been designing watches for over 10 years. I consider myself an expert in the field, having worked with some of the most renowned watch brands in the world. Throughout my career, I’ve designed hundreds of successful watch models and have a deep understanding of the entire design process.

In this article, I’m excited to share my expertise and provide you with a comprehensive guide on how to design a watch. Whether you’re a budding designer, a watch enthusiast, or simply curious about the process, this article will take you through the key steps and considerations involved in crafting a timepiece.

I’ll be drawing on my own experiences, as well as insights from other leading experts in the industry. So, let’s dive in and explore the art of watch design

Master the art from concept to creation. Explore styles, materials, movements & functions. Unleash your inner watchmaker

Designing a watch may seem daunting, but with some planning and knowledge of watchmaking, you can create your own unique and stylish timepiece. In this comprehensive guide, we will walk you through the key steps and considerations when designing a watch from scratch.

How to Design a Watch: Let’s Explore

Embark on your journey to watch design mastery with American Watch, your ultimate partner in bringing your vision to life. Whether you’re a budding entrepreneur dreaming of launching your line, enhancing an existing brand with bespoke accessories, or seeking unique gifts for your team, our expertise spans design, manufacturing, and marketing to support your every endeavor.

Dive into the realm of creativity and innovation by testing your concepts with a swift turnaround—design and create a watch in just 15 minutes, and witness your ideas materialize in a matter of days! Led by Pinion founder Piers Berry, our team meticulously crafts timepieces that exude timeless elegance and sophistication. Striking a balance between classic proportions and minimalist aesthetics, our designs embrace simplicity, allowing the intrinsic beauty of shapes, textures, and materials to shine.

At the heart of our philosophy lies the Pinion design code, a testament to our commitment to coherence and visual harmony across our diverse range of models. With each creation, we weave a narrative of style and refinement, ensuring that every watch speaks the language of impeccable craftsmanship and enduring quality. Join us in shaping the future of horology and let your imagination run wild as we embark on this exhilarating journey together.

Choosing the Watch Type

The first step is deciding what type of watch you want to design. Here are some of the main options:

Analog Watch

The traditional watch with hour, minute, and second hands. Choose between a simple 3-hand design or adding extra complications like a date window, subdials,x, or moon phase. Best for classic style.

Digital Watch

Displays the time numerally instead of with hands. Often includes other functions like alarms, timers, and stopwatches. Best for a modern or sporty look.

Smartwatch

Syncs with your smartphone to receive notifications and track fitness/health data. The Touchscreen interface allows for many customizable features and apps. Best for tech-savvy users.

Consider your target audience and the overall style you want for the watch when choosing between analog, digital, or smartwatch designs.

Selecting the Watch Features

Once you’ve decided on the watch type, the next step is choosing what features you want to include:

Timekeeping Elements

- Hour, minute, and second hands

- Date window

- Day of the week

- Moonphase

- Chronograph for timing

- Tachymeter scale

- GMT hand for additional time zone

Complications

- Alarm

- Timer

- Stopwatch

- Calendar

- Calculator

- GPS

- Heart rate sensor

- Sleep tracking

Smartwatch Capabilities

- Notifications (texts, emails, calls)

- Activity tracking

- Music storage and control

- Apps and games

- Weather

- Customizable watch face

Prioritize must-have features, limit unnecessary complications, and consider battery life restrictions for smartwatches.

Choosing the Watch Case Shape and Size

The watch case contains the internal workings and determines the overall look. Consider these factors when selecting the case:

Shape

- Round – Most common, classic style

- Square – Modern, graphic look

- Rectangular – Sleek, elegant look

- Oval – Unique curved shape

- Irregular – Asymmetrical or artistic shapes

Size

- Diameter for round cases

- Width and height for square/rectangular cases

- Standard sizes range from 28mm to 44mm

- Larger cases are sportier, smaller cases are more elegant

Thickness

- Standard thickness is 6-12mm

- Extra complications require a thicker case

Lug Width

- Where the watch band attaches to the case

- Common lug widths range from 16mm to 24mm

- Lug-to-lug length also impacts fit

Material

- Stainless steel – Most common, affordable, durable

- Gold, rose gold, platinum – Luxurious materials

- Titanium – Very lightweight but expensive

- Ceramic – Scratch resistant

- Plastic – For very inexpensive watches

Match the case shape and size to your design vision and target market.

Choosing the Dial Design

The watch dial is the “face” featuring the hands and display for reading the time. Dial design considerations include:

Color

- Silver, white, black – Most common neutral tones

- Navy, blue, green, red – Subtle pops of color

- Vibrant multi-color dials are also an option

Markings

- Hour indices or numerals

- Minutes marked on the outer edge

- Extra markings for complications like date, day, chronograph

Texture

- A smooth, matte finish is common

- Guilloché engraved patterns

- Textured sunburst effect

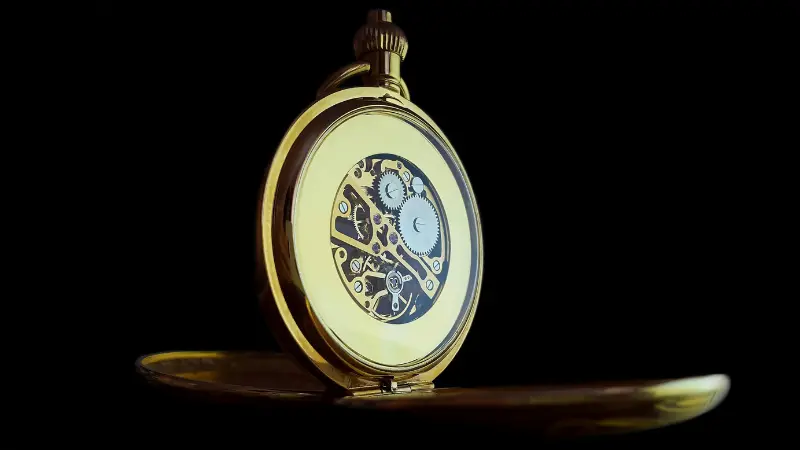

- Skeletonized cut-outs showing inner workings

Layers

- Single primary dial with a flat surface

- Multiple levels with subdials and inner discs

Experiment with different dial colors, textures, and layers based on your watch style.

Selecting the Watch Hands

The watch hands point to the time and come in a wide variety of styles. Key aspects to consider:

Shape

- Pointed stick hands

- Tapered sword hands

- Skeletonized cut-out hands

- Elongated baton hands

- Bold rectangular hands

- Retro curved hands

Color

- Matched to dial (silver, black, gold, etc)

- Contrasting color for legibility

Lume

- Glow in the dark coating usually on hour and minute hands

- Helpful for reading the time at night

Seconds Hand

- Usually thinner than hour/minute hands

- Can be a creative shape like an arrow or counterweight

Make sure the hands complement the dial design and are legible. The second-hand offers room for creative flair.

Choosing the Watch Strap or Bracelet

The watch strap attaches to the case and secures the watch to your wrist. Consider these key strap options:

Leather

- Classic material, many designs, and colors

- Durable leather maintains a beautiful patina over time

- Can be dressy or casual styling

Metal Bracelet

- Made of stainless steel, gold, or other metals

- Often with complex articulating links

- Durable and matches metal watch cases

Rubber/Silicone

- Sporty material comes in many colors

- Durable, flexible, and lightweight

- Best for active lifestyles, diving watches

Fabric/Nylon

- Woven nylon and other fabrics

- Provides a casual, outdoorsy look

- Breathable and comfortable for warm climates

Other Unique Options

- Exotic leather from ostrich or crocodile

- Natural materials like bamboo or cork

- High-tech aerospace-grade titanium

Match the strap to your design aesthetic – formal, sporty, elegant, etc. Interchangeable straps allow the owner to easily swap looks.

Selecting the Watch Movement

The movement is the complex inner mechanism that tracks time and powers the watch. The main options are:

Mechanical

- Mainspring-powered mechanical movement

- Found in high-end luxury watches

- Desirable for craftsmanship and prestige

Automatic

- Self-winding movement powered by the wearer’s wrist motions

- Eliminates manual winding needed for mechanical watches

- Complications add extra drain on the power reserve

Quartz

- Battery-powered quartz crystal regulated movement

- Very accurate and affordable

- The main choice for fashion watches

Smartwatch

- Tiny computerized movement

- Recharges its battery like a smartphone

- Controls smart functions and app integration

Consider accuracy needs, budget, and design goals when selecting the movement. Many luxury watches use finely crafted mechanical movements.

Creating Your Design Sketches

Now it’s time to sketch design concepts! Use these tips when developing initial sketches:

- Sketch by hand to easily generate and iterate through design ideas

- Focus sketches on case shape, dial layout, and hand styles

- Use colored pencils or markers to add color

- Draw both top-down and profile perspectives

- Sketch multiple variations to compare options

- Refine details in further iterations

- Maintain proper proportions for legibility

- Keep within reasonable production capabilities

Thorough sketches will create the blueprint for your watch design before finalizing technical drawings.

Developing Technical Drawings

After settling on a design direction, technical drawings are needed for manufacturing. Considerations for technical drawings:

Scale

- Use a standard 1:1 scale for full-size renderings

- Scaled drawings (3:1) can show interior components

Dimensions

- Include exact measurements for every watch component

- millimeters for small features, centimeters for case

Views

- Top view, side view, front view

- Perspective angles if needed

- Cutaway views to reveal internals

Materials

- Specify materials for case, crystal, hands, etc

- Include reference numbers to tie back to the bill of materials

Details

- All relevant details needed for manufacturing

- Surface finishes, engraving, texture patterns

- Any special assembly instructions

Comprehensive technical drawings are vital for translating your design into an actual working timepiece.

Prototyping and Testing

Creating a prototype is an opportunity to test your design in physical form:

3D Printing

- An affordable way to 3D print a plastic prototype

- Lets you evaluate the overall look and ergonomics

CNC Machining

- Carves a prototype case out of metal stock

- Useful for testing specific case materials

Hand Assembly

- Assemble a working model with real components

- Test functionality, legibility, and wearability

Digital Renderings

- Photorealistic 3D model created digitally

- Simulates real-world aesthetics virtually

Manufacturing Considerations

If your design is intended for commercial production, manufacturing considerations include:

Materials Sourcing

- Identify suppliers for cases, crystals, straps, movements

- Consider costs and minimum order quantities

Tooling

- Molds and machining fixtures needed for mass production

- Significant upfront investment for tooling

Quality Control

- Consistency in manufacturing quality is critical

- Implement testing procedures and standards

Certifications

- Water resistance, shock resistance testing

- Certifications help market the watch’s capabilities

Assembly

- Efficient assembly methods to meet production volumes

- Hand assembly vs automation

Early partnerships with manufacturers will help guide design decisions for real-world production.

Marketing and Branding

Bringing your watch design to market also requires marketing and branding strategies:

Brand Identity

- Name, logo, fonts, colors and styles

- Consistent look, feeling, and messaging

Advertising

- Paid ads to raise awareness, and interest

- Digital, print, out-of-home, and video ads

Social Media

- Engage and inform customers via social platforms

- Showcase features, lifestyle uses, and influencers

Product Photos

- High-quality lifestyle imagery

- Technical spec sheets

- Effective visual storytelling

Packaging

- Protects watch during shipment

- Premium unboxing experience

Build a recognizable brand that resonates with your target audience. Connect with consumers to make your watch design appealing and desirable in the market.

The Fundamentals of Watch Design

Understanding Watch Anatomy

The first step in designing a watch is to familiarize yourself with the various components that make up a timepiece. A watch is a complex mechanism, consisting of numerous parts that work together to keep time accurately.

Some of the key components include:

- The case: This is the outer shell that protects the internal workings of the watch.

- The dial: Also known as the face, this is the part of the watch that displays the time.

- The hands: These are the indicators that move around the dial to show the current time.

- The movement: This is the engine of the watch, responsible for powering the timekeeping mechanism.

- The crystal: This is the transparent cover that protects the dial and hands.

- The strap or bracelet: This is what secures the watch to the wearer’s wrist.

Understanding the role and function of each of these elements is crucial when designing a watch, as you’ll need to ensure they work together seamlessly.

Bringing Your Design to Life

Manufacturing and Production

Once you’ve finalized your watch design, the next step is to oversee the manufacturing and production process. This can involve working closely with watch factories, suppliers, and other partners to ensure that your design is faithfully executed and produced to the highest standards.

During this phase, you’ll need to consider factors such as:

- Material sourcing and procurement

- Manufacturing techniques and processes

- Quality control and testing

- Packaging and branding

Effective project management and communication with your production team will be crucial to ensuring a smooth and successful manufacturing process.

Branding and Marketing

In addition to the design and production aspects, creating a strong brand identity for your watch is also essential. This involves developing a cohesive visual identity, crafting compelling marketing materials, and effectively communicating the story and values behind your timepiece.

Some key branding and marketing considerations include:

- Developing a memorable logo, packaging, and product presentation

- Crafting a unique brand narrative and positioning

- Leveraging social media and digital platforms to reach your target audience

- Exploring strategic partnerships and collaborations to enhance your brand’s visibility

By investing in branding and marketing, you can ensure that your watch stands out in a crowded market and resonates with your target customers.

Conclusion

Designing a watch from the ground up is an exciting challenge that brings together aesthetics, engineering, and business considerations. Following the key steps outlined in this guide will take you from initial sketches to a tangible timepiece you can proudly wear on your wrist and share with the world. The watch design process enables you to apply creativity, thoughtfulness, and attention to detail.

Approach the process with patience to explore possibilities and produce concepts you’re passionate about. With diligent refinement of the technical aspects and positioning, you can develop a watch design that seamlessly merges visual design, function, and innovation.

Frequently Asked Questions

What design software is best for designing watches?

Some good options are Adobe Illustrator for drafting designs, Rhodia Drive for sketching concepts, KeyShot for creating realistic renderings, and CAD programs like SolidWorks for technical drawings.

What are the main parts of a mechanical watch movement?

The main parts are the mainspring as the power source, the gear train (wheels, pinions, escapement) to control the unwinding of the spring, the balances wheel that oscillates, and the hairspring that regulates the oscillations.

How accurate are quartz watch movements?

Quartz movements have an accuracy of +/- 10 seconds per month, much higher than mechanical movements which average +/- 5-30 seconds per day. The regular oscillations of the quartz crystal regulate the timekeeping.

What tools do watchmakers use?

Common watchmakers’ tools include loupes, tweezers, screwdrivers, microscopes, timing machines, pliers, precision hammers, polishing sticks, oilers, and staking sets used in watch assembly and repairs.

How long does it take to design and develop a new watch?

The typical timeframe for major brands is 12-24 months from initial concept sketches to having a final product ready for market. The design process itself may take 3-6 months.

Can I customize my watch?

Yes, customizing your watch is entirely possible through a selection of watch modification services and do-it-yourself kits. From the strap and bezel to the dial and hands, little touches can transform a stock watch into your signature piece.

Popular customizations include engraving watch cases or bands with names/dates, replacing parts with aftermarket options in alternate colors or materials, or even designing ornamental artwork for unique watch dials. The right watchsmith can even assist serious hobbyists build watches from the ground up.

Approachable starting points for first-timers include mix-and-match watch straps and bezel inserts needing no special tools. But even advanced custom builds like engraving metal parts or 3D-printing accessories enable complete personalization if desired. Websites like BespokeUnit or local jewelers facilitate bringing one’s vision to fruition through custom timepieces.

So for creative enthusiasts seeking distinction, custom watch building allows endless possibilities to craft a one-of-a-kind wrist statement. Begin simple or go all-out – the options await to make your watch truly your own.

Can you make a watch yourself?

Yes, it’s entirely possible for an amateur enthusiast to build a custom mechanical watch themselves with some dedication and specialized equipment.

Watchmaking projects range from basic customizations like new dials, hands, and strap changes to machining parts and assembling movements from scratch. Beginners can start simply by modifying the look of an affordable watch before advancing to more complex builds.

The foundation relies on quality watchmaking tools like jewelers’ loupes, tweezers, precision drivers, and rotating stands for accessing components. Sourcing movements, hands, dials, and casings from watch materials suppliers enables ambitious hobbyists to eventually construct full wristwatches themselves.

With practice, patience, study of horology techniques, and the right parts – creative do-it-yourselfers can craft custom timepieces reflecting their visions. Completed personal builds make meaningful keepsakes. So for the space and means, yes – building unique watches at home or a community workshop allows another level of personal expression through mechanical artistry.

How to start a wristwatch brand?

Starting a watch brand entails developing a compelling concept, designing quality timepieces, establishing manufacturing, building a marketing strategy, and distributing through targeted sales channels.

Clearly define your positioning – what makes your watches unique to discerning consumers in a crowded market? Focus first on your hero model that exemplifies the brand.

Vet component suppliers and manufacturers to produce small batches. Prioritize Swiss movements or reliable alternatives and proven cases/dials. Contract trustworthy factories for assembly until sales justify vertical integration.

Drive interest through social media and press via product storytelling and strong visual aesthetics. Seek influencer and forum feedback while directly engaging key groups: enthusiasts, professionals, style leaders, etc.

Allow limited distribution through niche watch retailers or your e-commerce site. Reinforce scarcity to elevate desire amid collectors. Reinvest revenue into additional model development.

With authentic passion, strategic partnerships, and commitment to quality craftsmanship – the foundations exist to build a sustainable watch brand and community over the long term.

What is the process of making a watch?

The watchmaking process involves the meticulous assembly of miniature components that make up modern mechanical timepieces. It requires skilled craftsmanship and quality hand tools.

Movements form the watch’s “engine”, crafted from gears, springs, screws, and plates. Watchmakers start by designing blueprints specifying part shapes and desired complications. These parts are then precisely CNC machined from metals before finishing via beveling, polishing, and decoration.

Additional components like dials, hands, and cases are tooled to perfectly fit the calibrated movement. Master watchmakers use loupes, tweezers, and screwdrivers to assemble the core movement, dial, and hands with hair’s width precision. Cases and crystals fully enclose each watch before extensive testing and synchronization ensues.

From initial ideation through its encasement, producing a single mechanical watch follows a journey spanning design studios, machining shops, and expert benchwork. Each step realizes the form and function that makes these tiny machines wearable kinetic art.

How do you become a watch designer?

To become a watch designer, one typically needs a combination of creativity, technical skills, and industry knowledge. A strong foundation in design principles, such as drawing, sketching, and computer-aided design (CAD), is essential. Additionally, gaining expertise in horology and understanding the intricacies of watch movements, materials, and manufacturing processes is crucial.

Many aspiring watch designers pursue formal education in industrial design, jewelry design, or horology from reputable institutions. Building a portfolio showcasing design concepts and projects, networking within the watch industry, and seeking internships or apprenticeships with established watch brands or manufacturers can also help aspiring designers break into the field.

Passion, dedication, and a keen eye for detail are key attributes for success in this competitive yet rewarding profession.

Can I design a watch face?

Yes, you can design a watch face! With advancements in technology and design software, creating your unique watch face has become more accessible than ever. Many online platforms and software tools allow you to design and customize watch faces according to your preferences, style, and creativity.

Whether you’re an artist, designer, or simply someone with a vision, designing a watch face offers an exciting opportunity to express yourself and create something truly personalized.